Still sleeping on the "efficacy bottleneck" plaguing your functional ingredients?

When you sink money into developing a wellness product, only for end consumers to feel zero tangible results because your ingredients have lousy absorption and poor stability — chances are, your delivery tech is the weak link. Today, though, liposome technology is shattering that bottleneck — and the innovative use of co-loaded liposomes, in particular, is shaking up the functional ingredient supply chain.

Different end-product formulations have wildly different demands for ingredient delivery systems. Thanks to liposomes' versatility, the industry's landed on targeted co-loading strategies (take Natural Field's product practices as a reference):

Triol-Type Rare Ginsenosides: Built for Powdered Beverages

This liposome formula plays nice with powdered beverage manufacturing processes and consumer use cases — it stays structurally stable when mixed with liquid, so the active ginsenoside compounds release efficiently.

Diol-Type Rare Ginsenosides: Perfect for Capsule Formulations

Capsules' sealed environment is ideal for storing this type of liposome — plus, it keeps stomach acid from breaking down the active ingredients, so the nutrients get absorbed precisely in the intestines.

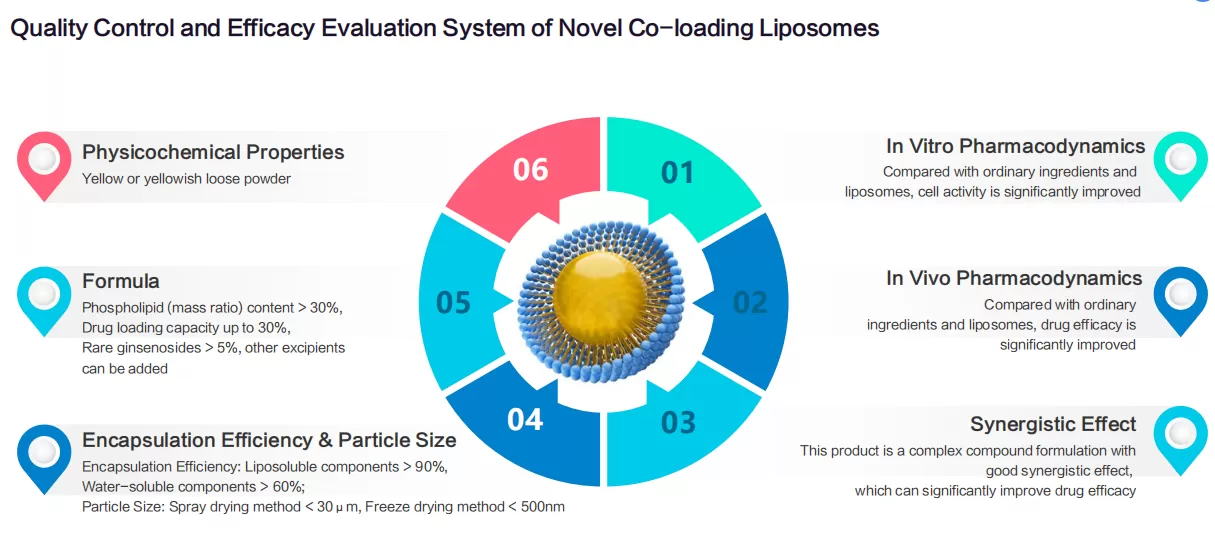

The value of liposome tech ultimately boils down to two things: stability and effectiveness. A robust evaluation framework is the backbone of quality control in B2B supply chains:

Efficacy Metrics: Dual Boost From Cell Culture to In-Vivo Performance

In-Vitro Pharmacodynamics: Compared to standard ingredients or basic liposomes, cell viability sees a meaningful jump.

In-Vivo Pharmacodynamics: Efficacy gets a measurable lift — so your end product actually delivers on its promises for consumers.

Synergistic Effects: As a multi-ingredient formulation, it pairs synergistically with various functional ingredients to amp up your product's overall value.

Quality Metrics: End-to-End Checks That Count

Formulation Design: Phospholipid content ≥30%, drug loading capacity up to 30%, and rare ginsenoside content ≥5% — striking a balance between potency and stability.

Encapsulation Efficiency & Particle Size: ≥90% encapsulation for fat-soluble ingredients, ≥60% for water-soluble ones; particle size tailored to your needs (<30μm for spray-dried blends; <500nm for lyophilized options).

Physicochemical Properties: Appears as a pale yellow to yellow fluffy powder, compatible with a wide range of manufacturing processes.

To meet the diverse manufacturing needs of end brands, liposome ingredients come in 3 core delivery formats:

Aqueous Solution: Works for liquid beverages, oral solutions, and similar formulations — ready to use right out of the package, cutting down on production steps.

Lyophilized Powder: Ideal for premium products — it's highly stable, and retains most of its activity once reconstituted.

Spray-Dried Powder: Easy to store and blend — the go-to pick for powdered beverages and compressed candy.

For B2B brands, liposome tech fixes 3 major pain points:

Boost Ingredient Efficiency: Ditch the waste of "high cost, low absorption."

Amplify Product Differentiation: Lean into "high-efficiency delivery" as a key selling point to stand out from generic competitors.

Expand Formulation Possibilities: Co-loading tech enables multi-ingredient synergy, making complex functional formulas a reality.

As a specialized supply chain partner in the functional liposome space, Natural Field offers end-to-end support — from co-loaded liposome ingredients to custom-tailored solutions — and aligns directly with end brands' formulation needs.

Whether you' re after triol-type ginsenoside liposomes for powdered beverages or diol-type blends for capsule formulations, our standardized quality control and flexible delivery formats let you launch high-performance wellness products quickly.

Reach out to us today to kickstart your liposome formulation innovation!